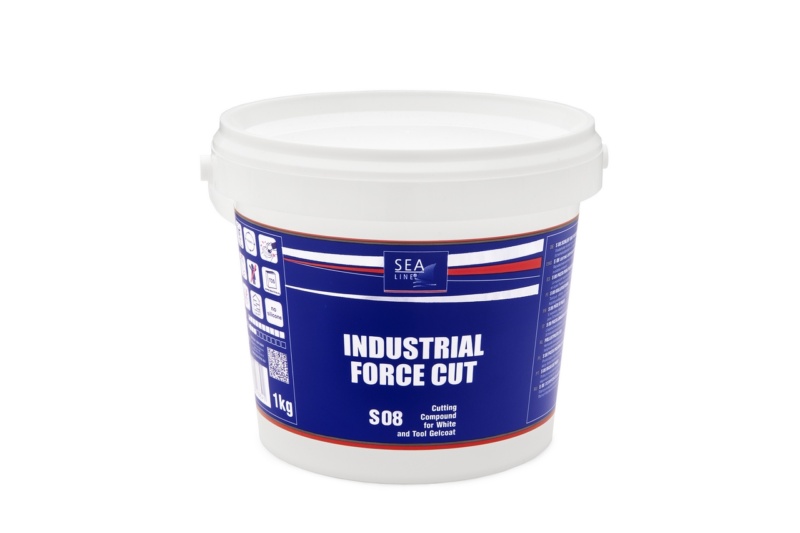

We starting new year with new product – polishing compound S08 INDUSTRIAL FORCE CUT.

Why S08 INDUSTRIAL FORCE CUT ?

This polishing compound have one the highest cut level, it allows to remove defects after using sand paper P600. It can be used on hardest surfaces, finished products made of laminate and for molds. Polishing compound will be especially used for light-colored surface.

For whom S08 INDUSTRIAL FORCE CUT ?

S08 INDUSTRIAL FORCE CUT was designed for manufacture which want to in fast way prepare products for next stage of productions.

Advantages S08 INDUTRIAL FORCE CUT :

We are expanding our offer by introducing two new products that will provide boat enthusiasts

Come and join us at METSTRADE 2023, METSTRADE the best event for marine industry professionals,

Visit us and our production plant without traveling

New in the 2023 season is a new polishing wool The new black and white

Yes, you can paint the bottom of the boat with polyurethane paint due to its high mechanical strength. We recommend this solution when the boat is not launched for a long time and is not exposed to fouling.

It is not recommended to apply 2K paints over 1K paints. 1K and 2K inks differ in their composition and properties, including hardness, chemical resistance and durability. 1K paints are one-component and dry by evaporating the solvent, while 2K paints are two-component and need to be cured by adding a hardener. Applying 2K paint over 1K paint can cause unpredictable chemical reactions and lead to undesirable effects such as dulling, chipping or flaking of the paint. Therefore, always use paints according to the manufacturer’s instructions and do not mix different types of paints. farby zgodnie z instrukcjami producenta i nie mieszać różnych rodzajów farb.