The offered EPOXY PRIMER SPRAY 2K is a 2-component epoxy primer with multifunctional applications.

This aerosol product allows for a professional spray application without the need for a compressor and paint gun.

| Capacity | Code |

|---|---|

| 400 ml | 300008758 |

| Surfaces | GRP, laminates, steel, aluminum | |

| Area | Above and below waterline | |

| Function | Grounding Intercoating Filling Antiosmotic Anticorosive | |

| Application | spray can | |

| Theoretical coverage for 400 ml | 1-2 м2 | |

| Number of coats | 2 – 4 | |

| Pot life 20°C | 48 h | |

| Time between layers without sanding | 5~10 minutes | |

Before triggering, shake can thoroughly for 2 minutes after agitation balls are heard.

Remove the red pushbutton from the cap.

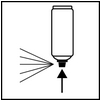

Turn the can by 180° and fit the pushbutton onto the pin in the base of the can.

After triggering, shake can again thoroughly for 2 minutes after agitation balls are heard.

Set the adjustable spray nozzle to the size of the damage and damage pattern.

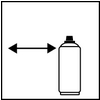

Spray distance: 10 ~ 20cm.

Standard application: approx. 2÷4 spray coats, recommended dry film layer: 80 ~200 μm

NOTICE: For antiosmosis and anticorrosion protection recommended DTF is 240 μm.

Allow a flash-off time of approx. 5-10 minutes between spray coats.

After painting, turn the can upside down and spray the valve until empty.

The completely empty spray cans can be disposed of in the recycling waste container.

Cans with hardened material must be disposed of as special waste.

This is a multifunctional paint that protects, enhances adhesion, and also protects against osmosis. Lightprimer

This particular product is recommended for protecting the laminate below the waterline, especially for repairing

We primarily recommend it for surface corrosion protection. The 4:1 epoxy anti-corrosion primer can be

Yes, you can paint the bottom of the boat with polyurethane paint due to its high mechanical strength. We recommend this solution when the boat is not launched for a long time and is not exposed to fouling.